Coating, adhesive manufacturing, and printing industries use UV lamps throughout their processes to cure or finalize their products for a long-lasting finish. These lamps rely on reflectors and quartz plates to work efficiently and concentrate the light or ensure comprehensive coverage of the work surface for a consistent process. While both parts are equally important, they serve different roles.

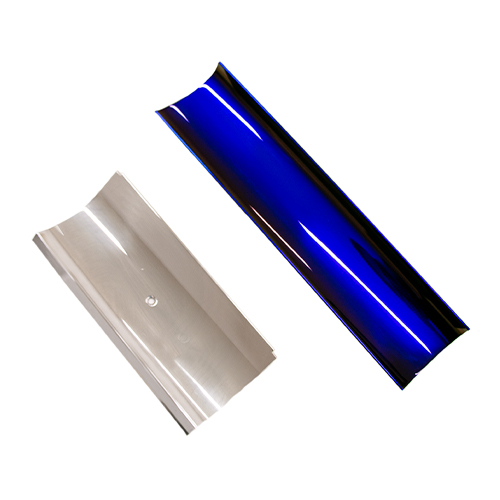

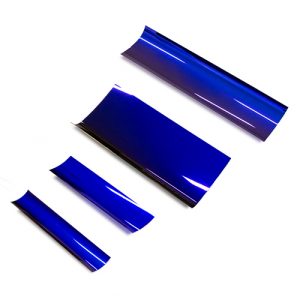

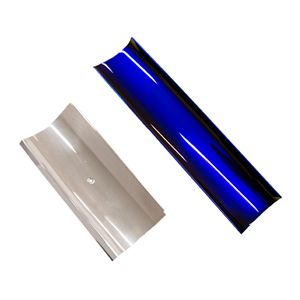

Reflectors, which are made from reflective metals or coated quartz pieces, direct the beam of UV light generated by a lamp in the direction of a specific target. Properly constructed reflectors also ensure the light is distributed evenly across the entire surface without gaps or weak spots. Some UV lamps also have heat control through dichroic reflectors. These reflectors have an aluminum or quartz lining and a dichroic coating, which allows infrared light through while reflecting visible light and redirecting heat away from the target area. But quartz plates protect the internal lamp components from ink particles, dust, and other contaminants. These components are clear and made from either quartz glass or fused silica substrates.

Learn more about the critical role of both components, their benefits, and the industries that rely on them.

Common Uses and Benefits of Reflectors and Quartz Plates

UV lamps are commonly used in the printing and coating industries to set ink or material coatings, curing them into a finished top layer that is smooth, longer-lasting, or has appealing finished characteristics. Adhesives manufacturers also use UV lamps, as many adhesives go through a one- or two-step curing process to create a long-lasting or more powerful bond.

Once you decide to incorporate UV lamps into your processes, it’s just as important to consider equipment with the right functional and protective elements. In UV lamps, quartz plates and reflectors are critical for creating products with a consistently high-quality finish. The key benefits of using reflectors and quartz plates in your UV lamps include:

-

- More efficiency: Reflectors can fine-tune the ultraviolet light so it consistently covers a target area and increases the intensity to the proper level without increasing power demand. Because reflectors allow for adjustments, they more efficiently use energy without wasting it on off-target surfaces or requiring more energy for a stronger beam of light.

- Better and more uniform coverage: High-quality coatings and print projects require consistency at every stage of production, including the curing period. Manufacturers can guarantee a more consistent output with reflectors, which concentrate and position the UV light properly. Protective quartz plates also affect uniformity, as they prevent debris and ink from interfering with the lamp’s internal workings or obscuring the light beam.

- Longer-lasting materials: Quartz plates primarily protect the internal components of UV lamps from contamination that can gum up the parts, cause additional wear, or otherwise interfere with operations. This increases the lifespan of each lamp. It also increases the cost-effectiveness of the UV light curing processes, as manufacturers don’t have to replace their lamps as often.

Industries That Commonly Use Reflectors and Quartz Plates

Multiple different industries rely on effective, long-lasting UV lamps to create their products. Some of the top industries we serve are:

Printing

Commercial and industrial printers often turn to UV LED curing for crisp, long-lasting images on a variety of media and products. Digital inkjet printing, screen printing (such as for t-shirts and fabrics), and flexo printing applications all benefit from UV lamps with light reflector materials and quartz plates.

Coating

Fine coatings can protect fiber optics and graphics for longer-lasting performance. Wood-filling coatings also benefit from UV lamp-curing processes.

Adhesive Manufacturing

The adhesives used in electronics need to provide secure adherence without excess product. UV lamps can cure sensitive adhesives for maximum performance.

UV Reflectors and Quartz Plates by Southern Lamps

UV lamp housings with reflectors and quartz plates last longer and provide more effective lighting. Along with uses in curing and printing applications, UV lamps are popular tools for sterilization, air purification, water treatment, and surface sanitation. With the right reflectors for concentrating the light and the right quartz plates for protecting the lamp’s components, your organization can benefit from better performance, greater efficiency, and operating cost savings. Contact us today to learn more about how we serve industries ranging from water treatment facilities to food and beverage manufacturers or request a quote to start your order.